What Kind Of Nails Are Used For A Fiber Picker

Types of Nails For Every Construction Project

Nov 09, 2020

A nail may appear to be the nigh straight-frontward item you'll use in construction. Its design is unproblematic: a point, a direct shank, and a head. They have been used since the days of ancient Egypt and for more than 5,000 years builders have turned to them to attach beams and joists to ane another.

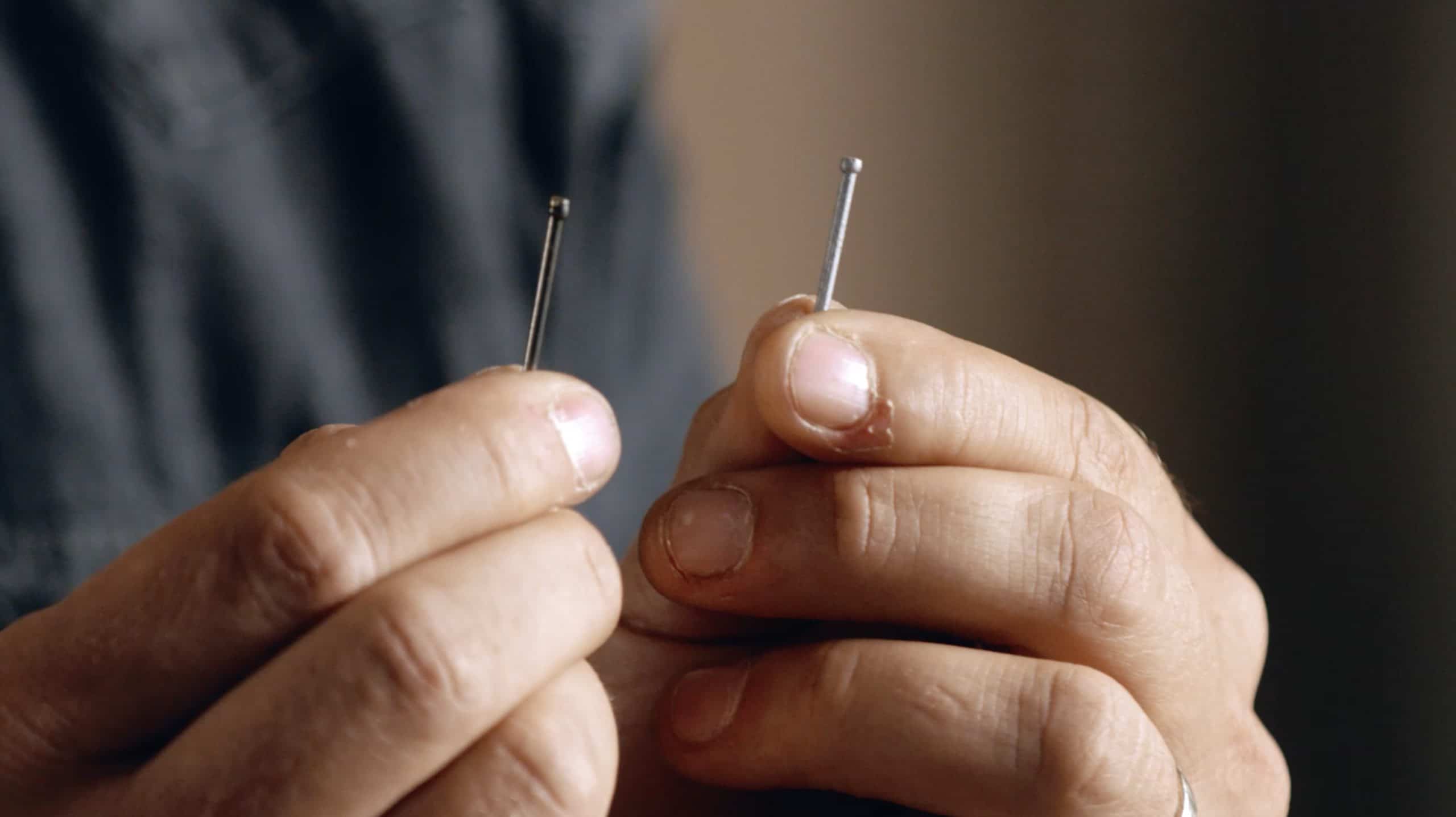

Yet, this virtually basic type of fastener also comes in a diversity of shapes and sizes, some best suited for structural frames and others used in stop carpentry work. As professional person builder and craftsman Jordan Smith explains, there are ones with "different tips, dissimilar shanks, and different heads, all depending on the purpose the blast was designed for."

Nail Materials and Coatings

In addition to unlike nail shapes, the dissimilar materials used to make nails and their coatings (or sheathings) brand them best suited to detail conditions and situations. At that place are a few dissimilar metals ordinarily used to make nails.

Steel

Nigh nails are made of steel, with several different options besides untreated steel.

- Stainless steel: The improver of chromium to steel helps it resist corrosion, though it can also reduce the gripping result of the smash.

- Galvanized steel: Galvanized steel is dipped in zinc, which provides a protective layer against corrosion. If steel nails are going to be used outdoors, you'll desire either stainless or galvanized ones.

- Carbon steel: The high carbon content of this steel makes it harder and is used for masonry nails.

Aluminum

This is another good option for outdoor use and is used to install aluminum siding and often with cedar and redwood. (The zinc in galvanized nails volition react with those forest, making aluminum a good alternative.)

Copper

These nails are most oft used on roofs as they are especially durable and resist the corrosive furnishings of pollution more than galvanized steel nails. They are more expensive than other options, but given that they can concluding for decades, they may be a better value over the long run.

Brass

This blend of copper and zinc does not rust and then it has long been used on ships. Given their cost, they are mostly only used in houses when they will be exposed and they provide a decorative accent. At that place are some rare situations where brass nails may be preferable over galvanized ones equally the zinc in galvanized coatings may react with sure materials, for case, the copper in copper pipes.

Other Metals

Some specialty nails are made of other metals, though they are not common in home construction. For instance bronze nails are oft used in the construction of boats while iron nails are still produced, but they are mostly used for the restoration of historic buildings.

Coatings

Simply as the materials used to brand nails tin can improve their performance under sure conditions, the aforementioned is true of some coatings that are commonly used. Notation that if a nail is described as "bright," that means information technology has no coating and is typically intended for indoor use.

Zinc

A layer of zinc over steel volition slow corrosion. While eventually the zinc volition vesture through, the rusting is delayed. At that place are two different ways in which zinc is typically practical:

- Zinc plating or electro-galvanization. When steel nails are dipped in a zinc acidic bath, a thin layer of zinc is left backside. This provides some protection against rust, though these nails are yet usually intended for indoor use.

- Galvanization. Galvanized or hot-dipped galvanized nails are dipped in molten zinc. The resulting layer is six times as thick as the layer on zinc-plated nails making galvanized steel nails advisable for outdoor apply. The layer of zinc is sometimes chosen a "sacrificial blanket" since, even if the underlying steel is exposed, the corrosion will attack the zinc before the nail itself.

Phosphate

Drywall nails are often coated with phosphate, which increases the gripping ability of the nails. (Note: phosphate coated nails should not be used on treated lumber.)

Cement

Also used on drywalls and gypsum lath, the sparse layer of cement on these coated nails heats upwards from the friction when they are nailed in identify, increasing their staying power.

Vinyl

A vinyl layer operates similarly to cement, although it has the added plus of acting as a lubricant for the blast during installation.

Nail Sizes

Nails accept their ain classification system, with a complete smash set ranging from 2d (1 inch long) to 60d (six inches). The "d" stands for denarius, a Roman penny—a reference to how much they one time cost—while the number assigned to a nail today indicates non only its length, simply also the diameters of its shank and head. A 16d or 16-penny blast, for case, is 3.5 inches long, has a shank with a diameter of 0.165 inches, and a head with a bore of 11/32 inches.

Specialized nails are often graded using the 2nd to 60d scale, though they may as well be sold indicating their length in inches or some other dimension.

Choosing the right size nail for your wood

As a general rule, more dense woods or hardwoods (including maple, oak, and walnut) are better able to hold nails every bit there are more fibers to grip the smash, though they are besides more than prone to splitting.

Softwoods (including cedar, Douglas fir, and pine) won't grip a nail besides because there are fewer fibers to hold information technology in place. You lot may recognize the softwoods as ones that are especially common in construction projects; they are popular choices because of the ease of working with these varieties, including when it comes to nailing fasteners. To recoup for the lower density of fibers, however, information technology is necessary to apply longer nails and in some cases coatings like cement as well.

Why don't structures fall down or come apart? Learn all about the stuff that holds edifice materials together in the MT Copeland online Fasteners and Adhesives grade. Taught by professional person builder Jordan Smith, the class covers topics ranging from nails and screws to glues and epoxies.

12 Types of Nails Used in Construction

There is an phenomenal diversity of nails, but described here are ones that contractors are most likely to run across, commencement with the common nail.

Common Nails

These nails, as well called common wire nails or construction nails, take straight shanks and flat heads. In home structure, common nails are usually used for framing and they are typically installed with a blast gun.

Duplex Nails

A duplex or double-headed nail appears to have two heads—or one elongated i. The lower caput rests confronting the surface of the wood it is nailed into, while the second caput is designed and then that the nails can be easily removed with a hammer or nail puller. Duplex nails are used for temporary structures, like scaffolding or concrete forms.

Sinker Nails

Most framing is built using common nails and a pneumatic gun, merely sinker nails are short, thin nails used in hard-to-accomplish areas. They are commonly coated either in cement or vinyl. "The friction heats up the nail, melts the vinyl coating, and makes for a smooth, like shooting fish in a barrel driving nail," Smith explains. "One time information technology's set, the rings at the top aid agree it in while the vinyl cools and solidifies, creating an adhesive bond."

Underlayment Nails

These nails are used to lay plywood floors or subfloors, either over existing flooring or atop wooden joists. They have thinner shanks, to minimize the gamble of splitting, just their virtually notable feature is the rings along their lengths. They give underlayment nails some of the benefits of a spiral, with greater gripping forcefulness than a straight nail.

Roofing Nails

These nails have heads that are disproportionately big compared to their shanks, helping them concur shingles or other covering materials in identify. Some covering nails have a small (often plastic) disk, non different a washer, underneath the head. This increases the expanse of the material that the nail keeps in place.

Annular Ring Nails

Also known as ring shank nails or drywall nails, annular ring nails have a series of rings along their shanks. When they are used with softwoods , the rings push the wood fibers out of the fashion when they are nailed in, and and then the wood returns to its place around the rings, holding the nail in place.

Spiral Shank Nails

Decking Nails

Like underlayment nails, decking nails are ringed. The design helps assure nails stay in place despite the drying and weathering conditions that decks are exposed to.

Masonry Nails

In order to drive a nail into cement or stone, you'll need a thicker shank like those with masonry nails. They as well have fluted or grooved shanks to assist them penetrate the hardest of surfaces. To install masonry nails yous'll demand a heavier hammer if not a power commuter.

Brads, Casing, and Finishing Nails

With thin shanks and minor nail heads, these nails are used for trim and other modest wood details. Brads are the thinnest of the three and best for situations where not splitting a piece of wood when you are driving a nail into it is your chief concern. They are used on picture frames, paneling, and narrow trim. A casing nail, the largest of the iii, is used when trim requires actress support, as with window frames and casings around door frames.

Box Nails

These nails with very thin shanks are also designed not to split wood; their proper name comes from their apply in building wooden boxes. They don't offer much back up and y'all won't use them in situations that crave structural strength. One common use in houses is when installing clapboard siding, as their thin shanks will non cause cracks.

Cut Nails

You lot'll most likely come beyond cut nails when working on a firm designed to take an old-fashioned menses feel. Also called square nails, they are cut from metal sheets instead of wire and were common in the nineteen thursday century though they are nonetheless produced today for a specialty marketplace.

MT Copeland offers video-based online classes that give you lot a foundation in construction fundamentals with real-world applications. Classes include professionally produced videos taught past practicing craftspeople, and supplementary downloads like quizzes, blueprints, and other materials to aid you chief the skills.

Source: https://mtcopeland.com/blog/types-of-nails-for-every-construction-project/

Posted by: ayalacalwascame.blogspot.com

0 Response to "What Kind Of Nails Are Used For A Fiber Picker"

Post a Comment